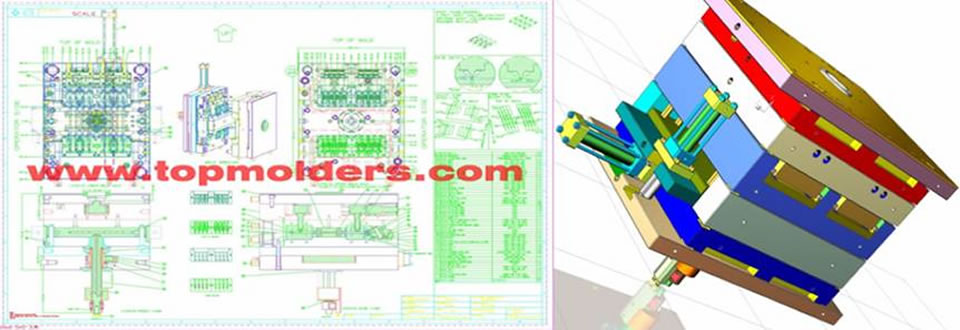

2d Mold Design

2d Mold Design

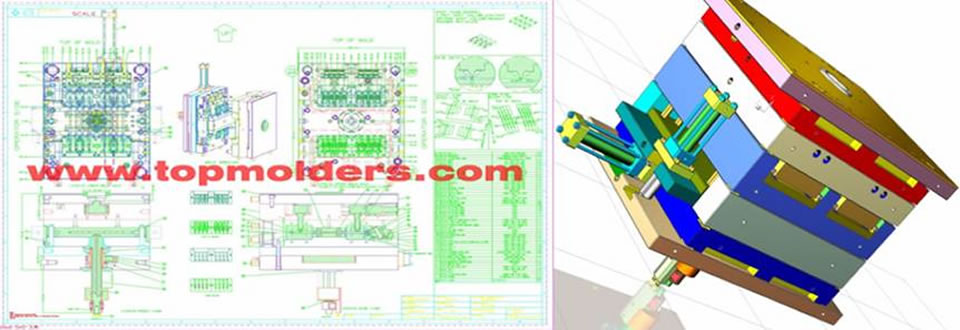

Topmolders Engineering supply complete 3D models, General Assemble drawing,

and set of 2D detailing of all machined parts, Bill of Materials (BOM);

modifications, manufacture support.

General Assemble drawing will be ready for the first time according

your specification and supplied information. To help you describe your

requirements fill out Mold Specification form, save and send Topmolders

Engineering.

1. Preliminary tool drawings:

The preliminary tool drawings should be assembly drawings containing

at least 2 plane views (injection side view + ejection side view) and

2 sections (longitudinal and transversal).

The preliminary drawings must show:

The functional design of the tool

The cooling system (incl. a separate clear cooling view)

The injection system

The tool dimensions

The lifting holes

Material/steel specifications

2. Final tool drawings:

The final tool drawings should be assembly drawings containing at least

2 plane views (injection side view + ejection side view) and 2 sections

(longitudinal and transversal).

The final drawings must show:

The functional design of the tool

The cooling system (incl. a separate clear cooling view)

The injection system (+ detail section of gates)

The ejection system

Hydraulic systems

Gas assisted systems

Electrical system hot-runners and connections

The tool and main part dimensions

Lifting holes and security details

Materials and heat treatment according to tool standard/steel specifications

Purchased parts including technical specification