What we do

Topmolders Engineering has the

full in-house capabilities of both part and tool design, our

designer could work with the customers develop from the

concept through production to get the result as client's

expected.

Topmolders Engineering offer the following service:

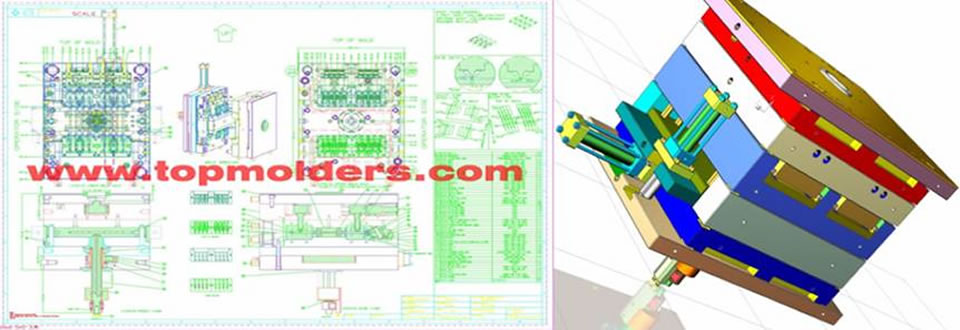

1. Mold Design ( 2D Mold Design / 3D Mold Design )

DME, HASCO, Yudo ,Hot Runner Mold design

PC / home appliance Mold design

Automobile / mobilephone Mold design

Commodity/double-layer Mold design

Multicolor product Mold design

Multiple cavity Mold design

Thermoset Mold design

Compression Mold design

Die-casting Mold design

2. Prototype, precision and high volume tools

3. Part / Product development

4. Cad Services

5. Moldflow Analysis

6. Reverse Engineering

7. EDM drawings/electrode modeling/CNC program

Using Software:

AutoCAD, SolidWorks, UniGraphic, Pro/Engineer, Moldflow

Customer Input:

Solid Files Direct to and from most CAD formats, IGES, STEP,

PARASOLID, DWG, DXF, JPG, TIF, PDF

Our Output:

Feasibility review: Part issues, Poor steel

condition, List the actions, Suggestion to simplify the mold

and to reduce the mold cost.

Concept drawing: Steel approval, Layout approval,

Approval for Slide / Lifter

Intermediate design: 3D Core for machining with

cooling and ejection, 3D Cavity for machining with cooling

and ejection, 3D Lifters, 3D Slides, 3D Mold base.

Final design: BOM (Excel sheet and in 2D drawing), 2D

assembly drawings, 2D detail drawings for non-standard child

parts.

|