Solid Modeling

Solid Modeling

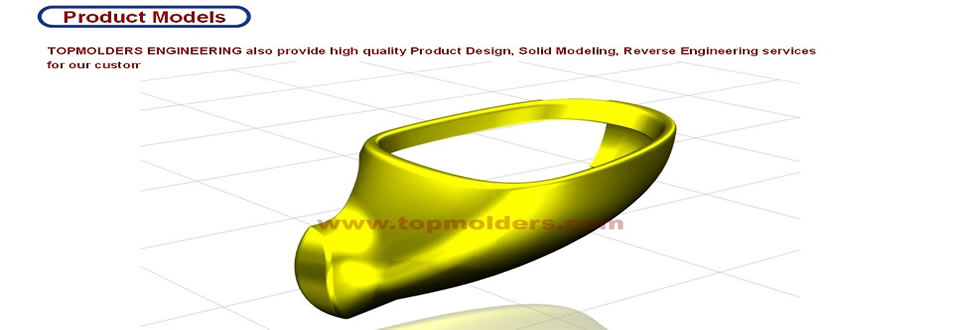

TOPMOLDERS ENGINEERING also provide high quality Solid Modeling services

for our customers...

In addition to offering mold design services Topmolders Engineering

can help with your piece part models. By utilizing the latest release

of Unigraphics mechanical CAD software we can produce 3-D solid models

of your piece part. These models can be developed from your paper drawings

or 2-D CAD data. The models are a 100% correct 3-D representation of

the final piece part showing all detail.

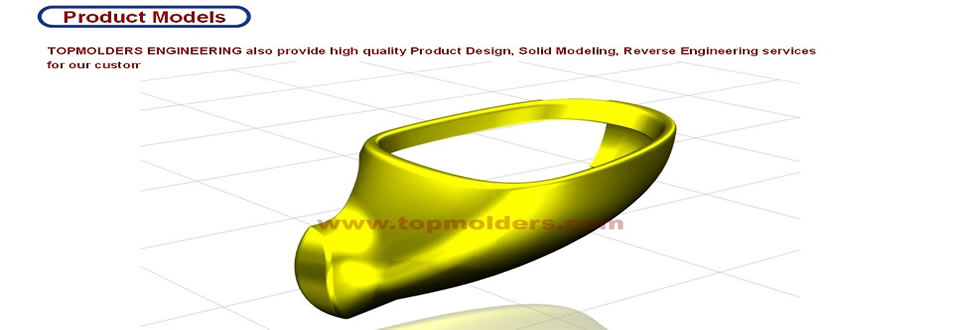

The 3-D solid piece part model can be utilized in a number of ways.

It can be used to develop engineering drawings for the product as well

as technical drawings for literature and maintenance manuals.

By doing so, we are able to design the

mold in 3-D, which allows the toolmaker to produce an accurate tool.

This prevents mistakes due to interpretation of the 2-D data or drawings

as well as reducing the design and build time required to manufacture

the tool.

The 3-D model can also be used for CAE processes such as mold filling,

cooling, and warpage analysis. Finite element stress analysis can also

be used to determine if the part design and chosen material will meet

the performance criteria required for proper product operation.

Clearance analysis can also be performed if all parts in an assembly

are modeled and mated together. This ensures that the product can be

assembled and will function properly.

If physical models are required the 3-D solid model can be used to develop

a rapid prototype model. This reduces or eliminates the costs normally

associated with making changes to completed tools to correct design

errors.

In addition to the technical analysis the 3-D model also has use in

marketing a new product. Photographic renderings based on the 3-D models

can be made to perform market analysis. These models allow people to

see lifelike pictures of the product prior to ever producing any physical

parts. By doing a market analysis based on the 3-D data of a virtual

product the cost and time required to market a new item can be reduced.

All of the above benefits can be used singly or in combination to ensure

that a product functions as intended. This will reduce the time and

cost required getting the product into the market place.